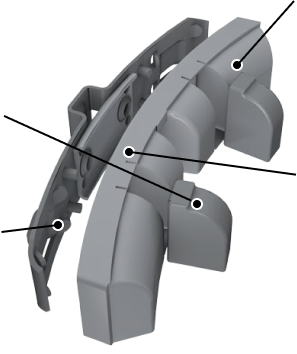

Brake shoe 2TP-155

with cast iron inserts

It is used as a replacement for cast-iron type “C” shoes. It has high and more stable friction coefficient in comparison with cast iron shoes. This makes it possible to use relatively low clamping force on the shoe to create the desired braking torque.

Iron inserts.

Heat removal from friction face, elimination of minor defects on the running surface of wheels

Frame.

Ensures the integrity and rigidity of the structure.

Friction material.

Has a relatively stable coefficient of friction at any speed and in all weather conditions.

Slots.

Prevent the formation of thermal cracks on the block, helping to remove the wear particles from the friction face.

More than 200 000 km of operation

Reliable figures in kilometers prove the quality of the product

Stable friction coefficient

Stable friction coefficient

Conformity certificate

Products meet all the requirements for vehicles

Systematic quality control

The product has been tested under extreme conditions in our own laboratory.

Brake pads for drilling equipment

Brake pad

Brake pad

Rival's

0,65

WEAR RATE (less is better)

0,78

43,0

HARDNESS EXTENT (within 30-55 HB)

18,9

5,0

SPECIFIC IMPACT VISCOSITY (more is better)

5,5

66,3

COMPRESSION RATE (more is better)

39,5

ACCEPTABLE

COEFFICIENT STABILITY DURING TRIPPING(100-700°С)

UNSTABLE

STABLE

CONDITION OF COUNTERBODY AFTER TESTS

COUNTERBODY DESTROYED

Disc brake pads

for commercial vehicles

Technological features

The products are manufactured under strict control using environmentally friendly raw materials and are tested in a modern laboratory with all the requirements according to international quality certificates, including the European certificate ECE R90.

Friction layer

Ensures stable coefficient and safety of braking at any temperatures

Underlayer

Protects the pad from overheating and ignition

Metal mesh

Removes the possibility of the friction material shearing away from the frame during operation

Steel frame

Is protected from corrosion by special powder coating

Long term of operation

More than 100 000 km

ECE R90 certificate

Product is fully certified

Stable friction coefficient

In a wide range of temperatures (up to 500°C)

Low disc wear

Over 300 000 km

Consistent quality monitoring

ISO/IEC 17025 certified laboratory

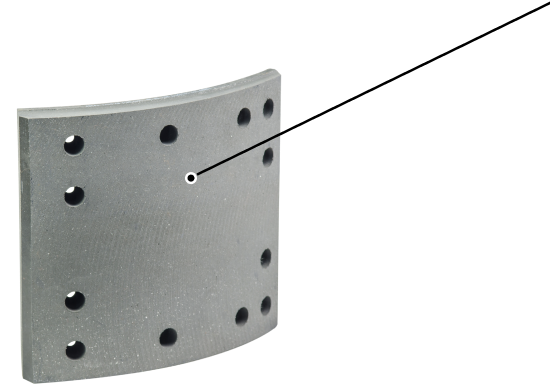

Brake linings

Comparative brake lining test

High quality raw materials

High efficiency braking

Long cycle

Compliance with European standards

Basalt mesh

USAGE OF BASALT MESH

Reinforcement of plaster layer

Reinforcement of horizontal wall seams

Reinforcement of roofing

Connecting multilayered walls (partitions)

Reinforcement of floor screed

Durability

Resistant to corrosion and rotting

Convenient transportation

8 times lighter than metal

Saving cement

Up to 30% for hollow materials

Low heat conductivity

No “cold bridges”

Resistance to aggressive environment

Concrete and alkalis

Brake pads

for BELAZ

FOR TRUCKS

With carrying capacity up to 450 tons

WORKING TEMPERATURE

Up to 500°C

MAXIMUM PRESSURE

8,7 MPa

LOW WEAR

1.15 mm per 200 brake applications

Friction material TR001

BRAKING EFFICIENCY

Test of friction material

Maximum application speed

50 m/s

Maximum disc temperature

Up to 450 °C

Long cycle

Up to 150 000 km

Maximum clamp pressure

80N/cm2

Disc type

Cast iron or steel