Raw materials from 18 countries

We use 6300 tons of raw materials per year, choosing only the best materials from global manufacturers. There are no boundaries for us when it comes to quality.

40

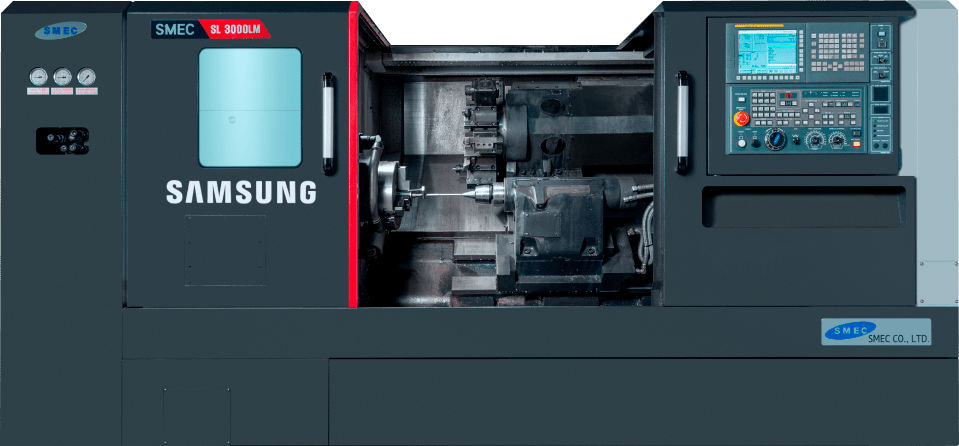

°Machine dosage

Mixtures with an accuracy of 99,9% ensures stable product quality at the very stage.

Complexity in simplicity

We make the simplest and most functional molds in the friction world using the best technologies and materials so that we can meet customer needs in the shortest time possible.

Lean approach in the organization

75 °С

50 min150°С

200 min160°С

300 min170°С

450 min200°С

600 min20°С

750 min6 post curing stages

Our pads go through 6 stages of vulcanization leading to the target level all the properties of the products, ensuring their stable operation in all conditions.

Test it yourself!

Select product to get test results

Where do we brake?

On wagons and locomotives. On trucks and semi-trailers. By buses and trolleybuses. By tram and metro. On tractors and combines. On drawworks and mine hoists. And most importantly - on time!